Overview

OEG's subsea service line regularly supports high resolution non-intrusive geophysical surveys for seabed route development, which includes the collection, processing, reporting and delivery of bathymetric data; seabed classification and detection of objects with dimensions of 0.25m and larger; identification and characterisation of the sub-sea floor to around 25m depth; sub-surface measurements at landfall and detection of larger scale anthropomorphic magnetic anomalies such as pipelines and wrecks.

OEG deployed a range of sensors including but not limited to Single and Multi-beam Echo Sounders (MBES), Side Scan Sonars (SSS), Sub-Bottom Profilers (SBP), and Magnetometers.

Client

GEO-4D

Location

Lowestoft, England

Workscope

OEG's subsea service line was contracted to provide MBES, SSS, SBP and Magnetometer survey services for a nearshore cable route corridor, south of Lowestoft approximating 5km in length.

Solution

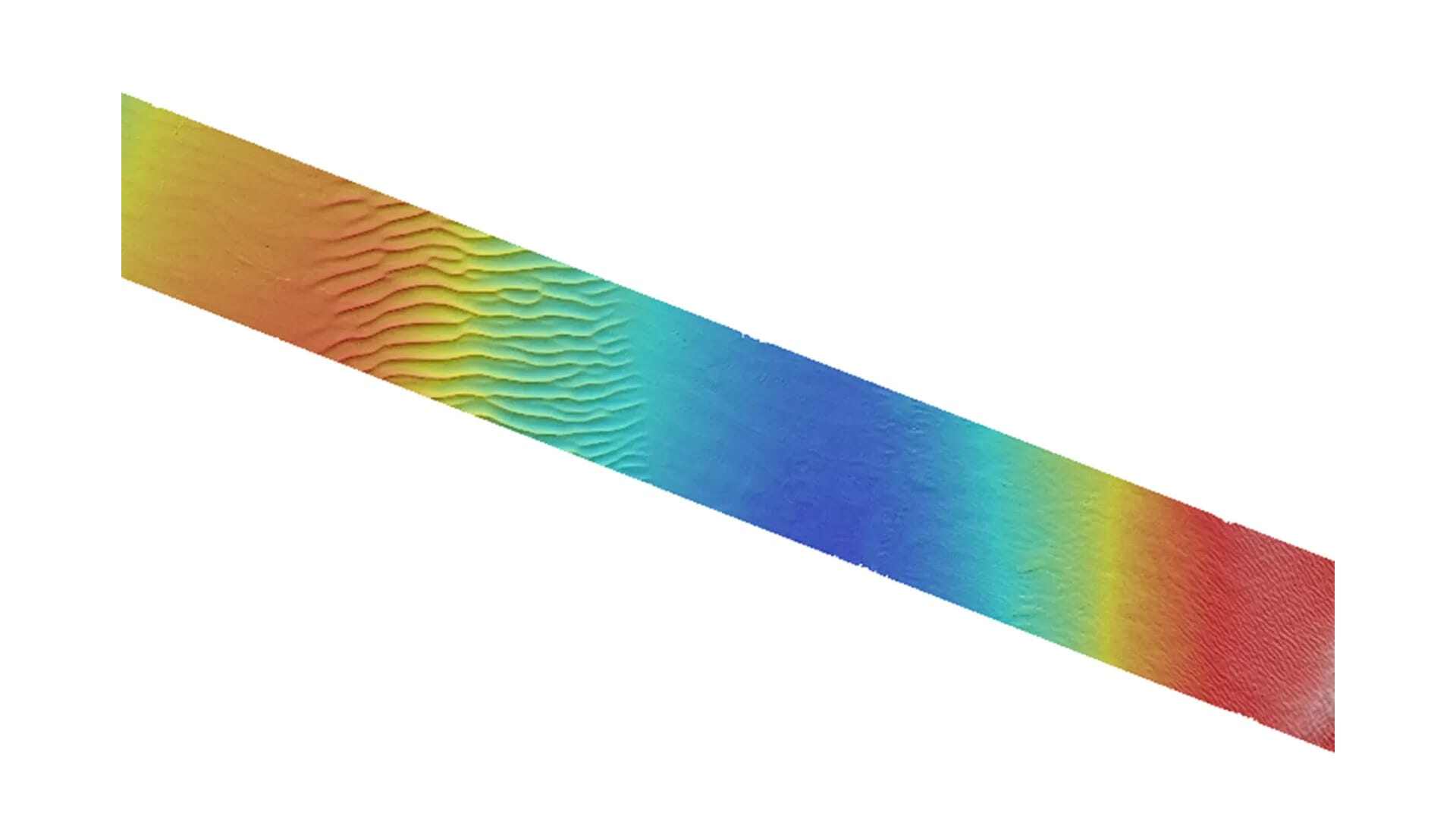

The MBES survey included the use of OEG's owned Norbit iWBMS shallow water MBES which is permanently mounted from a side arm on our 7m catamaran, Taran. MBES data was gathered in a 0.25m grid, utilising operational frequencies ranging from 200-700Khz to enable the most accurate definition of the seabed. The system was used in full range of 160° swath width with 256 equiangular beams which provided 4x the depth of usable swath coverage, meeting the criteria of IHO Special Order standard.

The MBES can operate within a minimum detectable range of 0.2m below the transducer, which made it perfectly suited to the Lowestoft project as the requirement included surveying shallow areas over high tide due to cable landing on the beach and therefore enabled non-intrusive survey data to be gathered.

Side Scan Sonar data acquisition was required to enable clear images of the cable lay zone and identify any potential areas where the cable was not buried sufficiently. For the works at Lowestoft, OEG Renewables utilised the single Edgetech 4125 Sidescan sonar which was soft towed from behind the vessel and positioned by USBL. Tow heights were maintained at approximately 5-10 meters from the seabed, which allowed for a high-resolution survey of the seabed.

OEG's subsea team opted to use this system because of the two dual simultaneous frequency sets available for the 4125. The 400/900 kHz set is the perfect tool for shallow water survey applications, providing an ideal combination of range and resolution. The 600/1600kHz set is ideally suited for customers that require ultra-high-resolution imagery in order to detect very small targets (SAR).

OEG utilised a single Geometric G882 Magnetometer which was soft towed behind the vessel and positioned with USBL. The Magnetometer was towed 2-5m above the seabed which allowed for the most accurate identification of surface or partially buried ferrous objects.

The team utilised a SES Innomar Standard parametric SBP profiler which was pole mounted to the Taran to identify depth of burial of the cable, lines were run every 50m crossing the cable route at 90 degrees.

Testimonial

Overall we are very pleased with how this project turned out. During our post-survey wash up meeting we discussed the positives of the geophysical-survey spread set up with seamless data collection across all instruments. We were able to deliver the data swiftly, efficiently, on-budget but most importantly to a standard the client was delighted with. The client was also very pleased with our operational work, as during data collection we incurred no standby days, which was down to our efficient planning around weather windows.