Welfare solutions

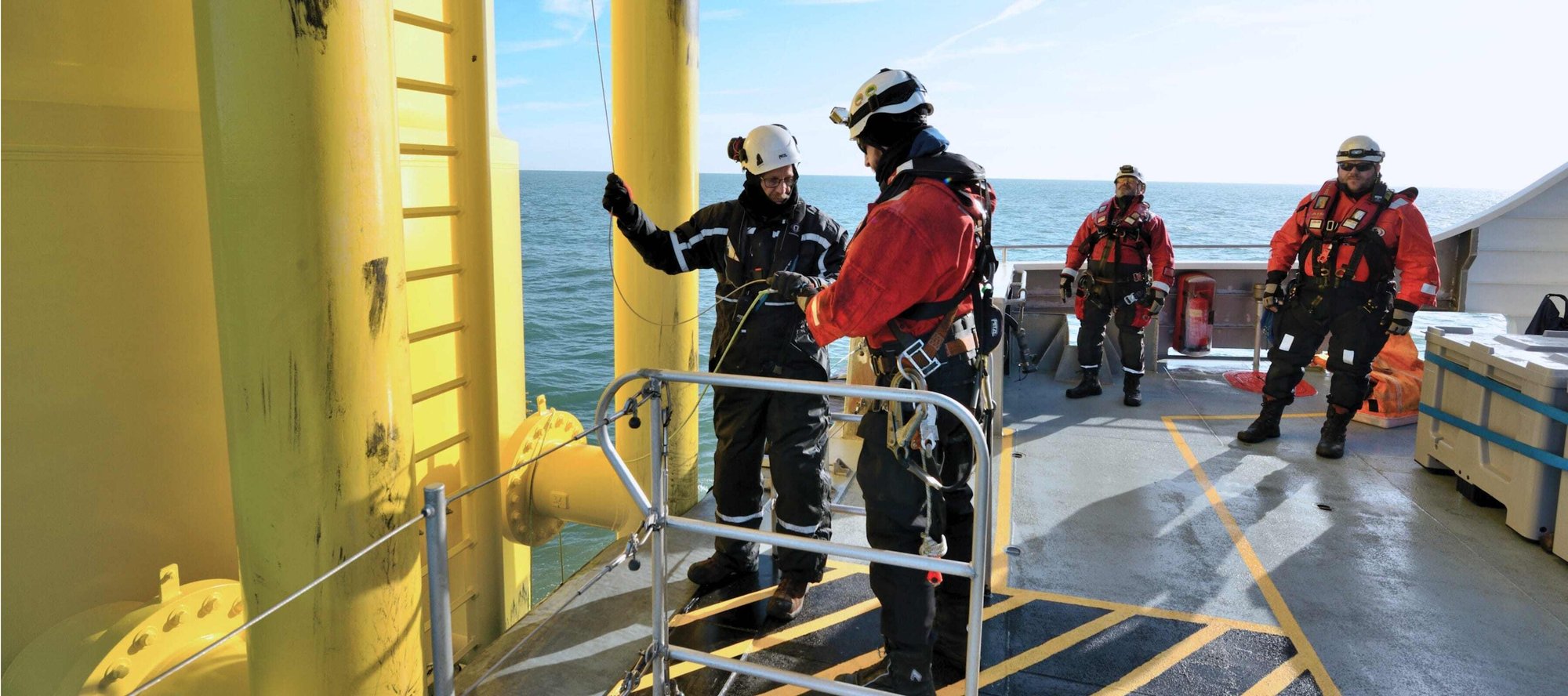

Portable welfare solutions manufactured for offshore environments.

Overview

We supply of industry-certified and patented In-Tower toilet cubicles and crane-able portable welfare units.

Our innovative offshore welfare units provide an essential solution to a long-term issue on offshore energy projects; our complete service includes installation and maintenance of our rental and sale welfare units.

%20(1100%20x%20830%20px)%20(1200%20x%20675%20px)%20(1800%20x%20800%20px)%20(1920%20x%201080%20px)%20(1920%20x%201080%20px)%20(1360%20x%20705%20px)%20(1920%20x%201080%20px).jpg)

Welfare units

In-tower toilet

The world’s first patented retrofit toilet for installation in a wind turbine tower. The In-Tower Toilet Unit is available in flatpack or fully built form to suit the stage of construction the windfarm is at. These units can be installed at pre-assembly or by installation technicians offshore. Once installed, the units operate using a cassette system - these cassettes are sealed and can be easily transported offshore.

In-tower toilet

The world’s first patented retrofit toilet for installation in a wind turbine tower. The In-Tower Toilet Unit is available in flatpack or fully built form to suit the stage of construction the windfarm is at. These units can be installed at pre-assembly or by installation technicians offshore. Once installed, the units operate using a cassette system - these cassettes are sealed and can be easily transported offshore.

The world’s first patented retrofit toilet for installation in a wind turbine tower. The In-Tower Toilet Unit is available in flatpack or fully built form to suit the stage of construction the windfarm is at. These units can be installed at pre-assembly or by installation technicians offshore. Once installed, the units operate using a cassette system - these cassettes are sealed and can be easily transported offshore.

Welfare multi-unit

Our Welfare Multi Units are fitted with a bespoke in-built lifting frame that is tested under DNV standards and fitted with LOLER inspected rigging for lifting them onto assets offshore. These units offer welfare facilities on larger assets such as OSP’s during construction phases or particularly busy campaigns throughout O&M phases. The welfare units are rotated between on and offshore for cleaning and servicing at every port call.

Welfare multi-unit

Our Welfare Multi Units are fitted with a bespoke in-built lifting frame that is tested under DNV standards and fitted with LOLER inspected rigging for lifting them onto assets offshore. These units offer welfare facilities on larger assets such as OSP’s during construction phases or particularly busy campaigns throughout O&M phases. The welfare units are rotated between on and offshore for cleaning and servicing at every port call.

Our Welfare Multi Units are fitted with a bespoke in-built lifting frame that is tested under DNV standards and fitted with LOLER inspected rigging for lifting them onto assets offshore. These units offer welfare facilities on larger assets such as OSP’s during construction phases or particularly busy campaigns throughout O&M phases. The welfare units are rotated between on and offshore for cleaning and servicing at every port call.